Words by SODA team

27 Jun 2025

Jake Inglis on Resilience, Reinvention and Designing for Everyone

Every story has a start. Sometimes it is a fortuitous one, sometimes a lucky one, or in the case of Jake Inglis it was, in fact, a devastating one, a setback that for some might derail dreams rather than fortify them.

At the age of 17, during a routine hockey match, Jake collided hard and felt a sharp crack in his spine. In an instant, the Scottish teenager became a patient in a hospital bed, facing a T12 vertebral fracture and months in a wheelchair. “Being an athlete who’s used to moving all the time, to becoming unable to move at all, was incredibly frustrating,” he recalls.

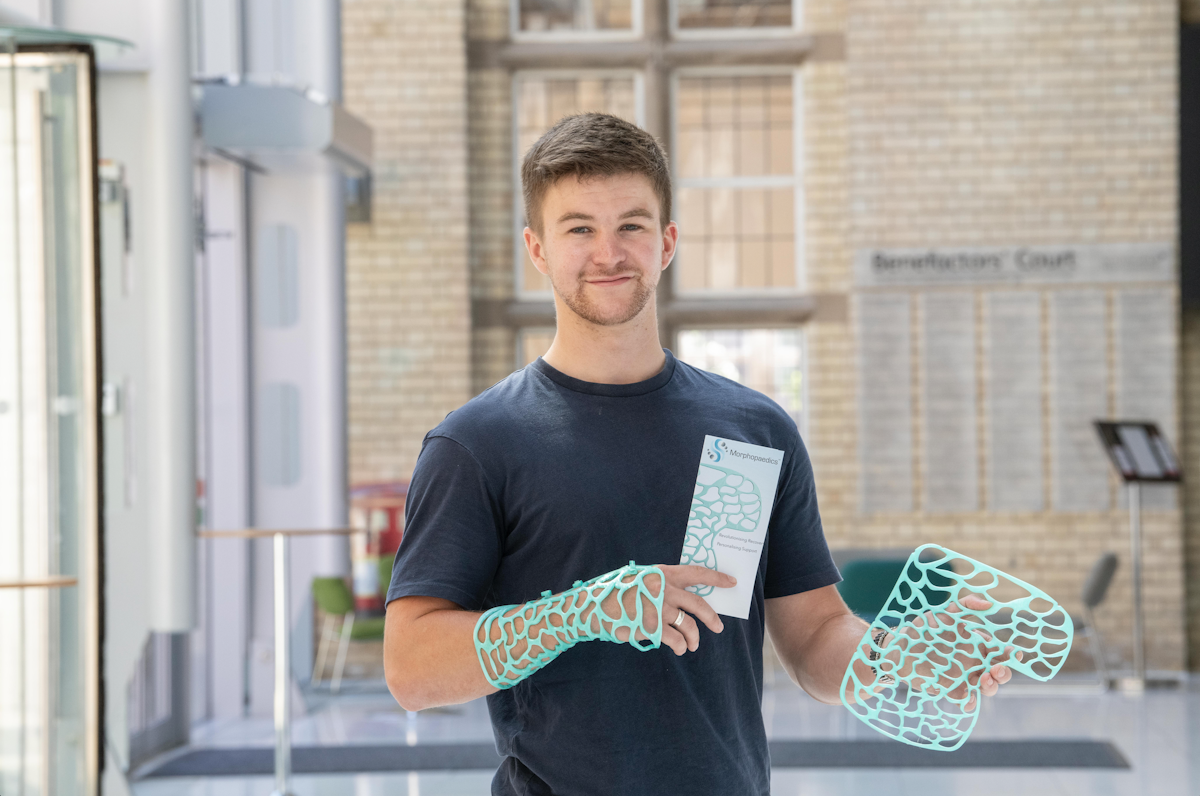

That early injury became the catalyst for an entirely new direction. In the five years since, Jake has transformed from patient to designer, turning personal trauma into innovation. Now 22, he’s developed a breakthrough orthopaedic cast — fittingly named Morphopaedics — that promises to improve patient recovery and ease burdens on the NHS. Blending a survivor’s empathy with an engineer’s ingenuity, Jake has built an identity rooted in the idea that better design can help heal people. “Being immobilised and going through rehab gave me a deep understanding of the frustration and isolation that patients feel,” he says.

He’s taken pain and molded it into purpose.

Credit: Jake Inglis

Breaking Point

In a rehabilitation center in Edinburgh, Jake relearned how to walk. The process was slow, with sessions of painstaking physiotherapy, progress came in inches. Immobilised in a wheelchair, he became acutely aware of design flaws that most healthy people never notice. “I saw how clunky and outdated a lot of medical gear was,” he says. “You’re already hurt and vulnerable, and then the devices meant to help you can end up reminding you of everything you can’t do.”

The months of dependency and adaptation gave him empathy for patients and a frustration with the status quo.

Jake’s rehabilitation wasn’t just physical—it was mental. By the time he was walking unassisted, he knew he wanted to make something better. That realisation led him to enroll in Product Design at Nottingham Trent University, determined to gain the skills to turn his hard-won insights into reality. The broken back had broken much, but it also opened up a new path.

He had lived through a problem firsthand, and he was setting out to solve it.

Morphopaedics: Breaking the Mold

Credit: Jake Inglis

In his final year studying BSc (Hons) Product Design (SW) at NTU, Jake’s mission took shape - literally - into a product. He developed a fully customisable orthopaedic cast that could be formed directly on a patient’s limb, almost like a second skin. He named it Morphopaedics, a nod to both morphology (form-changing) and orthopaedics.

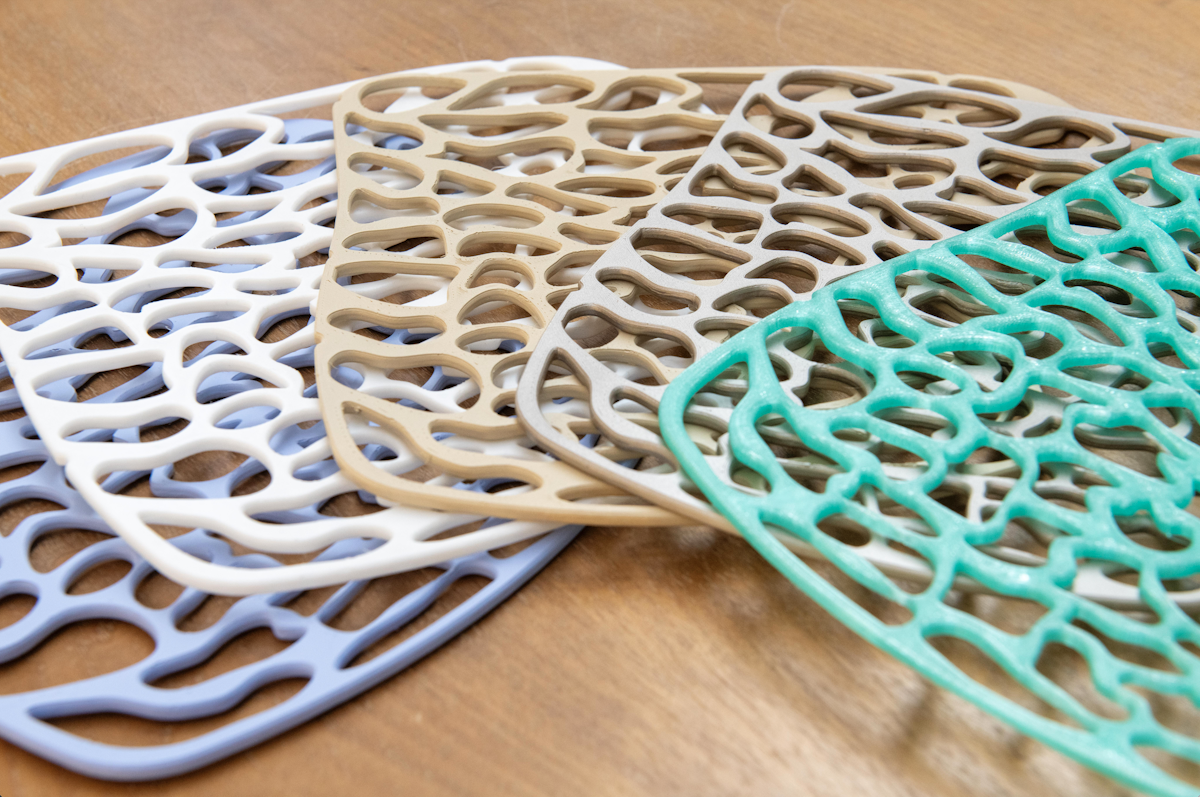

The device is a lattice-structured forearm cast, lightweight and water-resistant, which means patients can shower and maintain hygiene with ease. Unlike the heavy, itchy plaster casts of old, Morphopaedics is breathable and hypoallergenic, with smooth edges that won’t dig into your skin. It’s also easily removable and re-fastenable, so doctors and therapists, or the patients themselves, can adjust it as swelling goes down or muscles strengthen. In short, it moveswith the healing body, rather than locking it in place and hoping for the best.

Jake took inspiration from nature’s own designs. The interior of bone is a latticework; strong but light. A bird’s wing bones or a honeycomb – structures like these taught him that you can achieve strength without bulk. “In nature, nothing is wasted. Your bones are mostly hollow, yet they support you,” he explains, running a hand over the criss-cross pattern of the cast. That insight led to Morphopaedics’ distinctive webbed look: a biomimetic pattern that optimises support while minimizing material. The result is not only lighter for patients, but smarter for doctors. Because the cast is radiolucent (nearly invisible to X-rays), an arm encased in Morphopaedics can be X-rayed without removing the cast. Fewer removal-and-recast cycles mean less hassle and pain for patients—and less work for medical staff.

Credit: Jake Inglis

From the start, Jake designed and engineered Morphopaedics with both patient and provider in mind. Every feature seems to answer a real-world gripe. Traditional casts must stay dry; Morphopaedics can get wet. Old casts need a saw and brute force to take off; Morphopaedics unclips in seconds. Plaster casts crack under pressure or temperature swings; Morphopaedics’ high-grade Nylon 66 can handle daily life and then be recycled when its job is done. He even considered hospital logistics: up to 40 of his lattice casts can be nested and stored in the space of just 5 old plaster casts, freeing up precious storage and sterilization space in clinics. Multiply those efficiencies across a busy trauma ward, and you’re looking at a noticeable reduction in workload and cost for the healthcare system.

“There’s a huge opportunity here to modernise a process that hasn’t changed in decades,” Jake says of fracture care. “Medical imaging has advanced exponentially – casting hasn’t. I want to change that.”

Early feedback has been encouraging. Doctors and nurses who saw Morphopaedics in action immediately grasped its potential. Some noted how it could streamline fracture clinics, meaning fewer cast replacements, fewer follow-up appointments just to change wraps, fewer technicians needed to mix plaster. For an overburdened system like the NHS, those incremental savings of time and money could add up to a big impact. Jake’s project was showcased at NTU’s annual design exhibition, where it stood out for its practicality and purpose. Now, after a successful 3D-printed prototype and countless hours of refinement, he is securing patents and gearing up for the next stage: injection-molded manufacturing at scale. It’s not every day a student project edges toward real-world production, but Morphopaedics is on that trajectory.

“This cast was born out of a belief that we can do better – both for patients and for the healthcare system,” Jake says, reflecting on how far the idea has come.

Beyond the Cast

With his undergraduate chapter closing, Jake is on the cusp of a new adventure. He’s won a coveted 1851 Research Fellowship to pursue a Master’s in Innovation Design Engineering (IDE) at Imperial College London, where he’ll dive deeper into design engineering and bring Morphopaedics to the next level.

Technology will be a big part of his next steps. He’s particularly interested in how AI and advanced computing can supercharge design. For instance, he envisions using AI-driven algorithms to optimize future cast designs or even tailor them to individual patients in seconds. But he’s no wide-eyed technocrat; he tempers this excitement with caution. “AI can crunch data and show patterns I might miss,” Jake says, “but it doesn’t understand people on its own. It’s a tool, not a designer.”

Hand-in-hand with technological innovation is Jake’s commitment to sustainability. He often brings up the circular economy when discussing the future of design. The healthcare industry, he points out, is awash in single-use materials—from disposable plastic syringes to plaster casts sawed off and tossed in a bin. With Morphopaedics, he made sure the cast could be recycled and potentially re-formed into new casts, aligning with circular principles. It’s a small start, but it reflects a larger ethos: designing products with their full lifecycle in mind.

As he looks ahead to Imperial and beyond, Jake carries with him the lessons of the past few years: that empathy is as important as expertise, that a fresh pair of eyes can remake an old problem, and that the tools of design and engineering are most powerful when guided by a compassionate hand.

Still Standing

Credit: Jake Inglis

Now a London-bound graduate, Jake reflects on how far he’s come since that day on the pitch. What began in pain has become something else entirely: a source of drive, a well of ideas, a new way to contribute. “Five years ago I was learning to walk again,” he says. “Now I’m designing things that might help someone else get back on their feet. Honestly, I can’t imagine anything more exciting than that.”

And the best part is, he’s only just getting started.

- https://www.linkedin.com/in/jakeinglis/ - Jake on LinkedIn

- https://linktr.ee/jakeinglisdesign - Jake's Linktree

- https://www.jakeinglisdesign.com/morphopaedics - Further reading on Morphopaedics